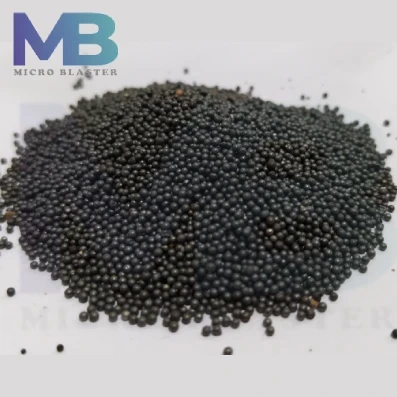

Stainless Steel Shots

Stainless steel shot alpha is constructed by means of a melting process & subsequently reshaped into spherical grain particles. Its austenitic microstructure guarantees its long service life. It is employed wherever ferritic residue (rust film, coloration) ought to be evaded.

| Product | Stainless Steel Shot |

| Shape | Round |

| Density | 7gm/cc |

| Melting point | 1450-1500ºC |

| Hardness | 47 HRC |

| Size | 0.075-2mm |

| Country | India |

| Brand | Micro Blaster |

- For aluminum, bronze, metal, zinc & stainless steel castings.

- In the aluminum, metal & stainless steel forgings.

- For aluminum extrusion & stainless steel profiles.

- To clean aluminum & different non-ferrous parts.

- For surface finishing of stainless steel parts.

- For zinc pressure die castings.

- For usage in blast cabinets.

- An option for glass beads.

Introduction of Stainless Steel Shot

Stainless steel shot is a spherical media that shot peening & cleans fast & actually. It is invulnerable to fracture & discourages surface contamination. (Stainless steel shot is obtainable in AMS-S 13165, SAE J 441, and AMS 2431/4 certificates.) Stainless steel shot alpha is constructed by means of a melting process & subsequently reshaped into spherical grain particles. Its austenitic microstructure guarantees its long service life. It is employed wherever ferritic residue (rust film, coloration) ought to be evaded.

Stainless steel shot scheduled for shot blasting machine methods on non-ferrous metals & stainless steel parts. This money-saving stainless steel abrasive media constructs Micro Blaster as most advantageous alternative for cleaning, desanding, deburring & finishing of non-critical alloys, in adherence accompanied by the considerable exacting specifications.

Companies casting & fabricating stainless aluminum & light alloy elements could safely utilize stainless steel abrasives since they strand no ferrous remnants contamination & achieve effective blasting interpretations. Stainless steel abrasives are extremely durable & are employed for deburring, blast cleaning & exterior finishing. Usefulness of stainless steel shot & steel grit decreases danger of rusting, though it can't guarantee complete withdrawal of oxide scale residue. Absolute pickling remains necessary for maximum erosion resistance.

Stainless Steel Shot Size

| Mesh | Sieve Size (mm) |

| 8 | 2.36 |

| 10 | 2.00 |

| 12 | 1.70 |

| 14 | 1.40 |

| 16 | 1.18 |

| 18 | 1.00 |

| 20 | 0.85 |

| 25 | 0.71 |

| 30 | 0.60 |

| 35 | 0.50 |

| 40 | 0.425 |

| 45 | 0.355 |

| 50 | 0.30 |

| 80 | 0.180 |

| 120 | 0.125 |

| 200 | 0.075 |

Stainless steel shot creates the widest scope of blasting abrasive on the market to be utilized both on turbine & on compressed air machines: spherical and angular stainless steel shot types offer the most advantageous technical & economic resolution for client applications. Appropriate for abrasive blasting machine operation stainless steel & non-ferrous metals, where maximum resistance to corrosion and/or less confrontational methods are required. Comprehensive durability of graninox chrome nickel produces a stable work-mix & uniform exterior finish.

Stainless steel shot in assorted diameters for tumbling, burnishing, sand blasting machine operation, metal finishing, & other applications. All stainless steels are alloys comprised mainly of iron, a small quantity of carbon & a minimum of 10.5% chromium, in complement to changing amounts of additional elements such as nickel, manganese, niobium, titanium, & molybdenum. Micro Blaster could assemble materials to traditional specifications by appeal, in reserve to tradition designs for commercial & analysis applications & unique proprietary technologies. Micro Blaster offers traditional grades of stainless steel shots, including Mil Spec (military grade); ACS, Reagent & Technical Grade, Food, Agricultural & Pharmaceutical Grade, Optical Grade, & observes applicable ASTM testing standards.

Stainless Steel Shot Abrasive

Stainless steel shot is a specialist component of the abrasive media for exterior preparation. Stainless steel shot abrasive is a structure of abrasive media employed to shot peen, clean, & polish metal items. It is well-known for its durability, resistance to deterioration, & capability to leave a livery & consistent finish on metal surfaces. Stainless Steel Shot Market serves a broad coverage of sectors, inclusive of automotive, aerospace, & metal fabrication, wherever grade & accuracy of surface finishing are demanded for outcome interpretation & appearance.

Stainless steel shot contains an assortment of applications. With industries stressing significance of shot peening machine operation & exterior rehearsal in extending the fatigue life & erosion resistance of metal elements, can innovate by presenting stainless steel shots with progressive features like collected hardness levels & enhanced spherical shapes. Furthermore, the demand may leverage on growing usefulness of stainless steel shot in sectors such as medical devices, where exterior cleanliness & precision are critical. Collaborations accompanied by manufacturers from other industries, advances in shot peening technologies, & creation of specialty stainless steel shots for exhaustive purposes all provide options for market participants to contribute to growth of externals preparation processes. Stainless steel shot may be segmented established on shot size, application techniques, & end-use industries. Surface preparation essentials vary from small, delicate elements to enormous metal structures, & several shot sizes are available to meet these needs. Wheel blasting, air blasting, & tumbling are instances of application methods certain show the variety of techniques utilized in exterior finishing operations. Automotive, aerospace, foundries, & medical devices are standards of end-use sectors that have unique shot peening & exterior preparation needs. This segmentation strategy allows manufacturers to deliver a combination of custom-made stainless steel shot outcomes certain fulfill particular exterior finishing requirements of various sectors in competitive Stainless Steel Shot Market.

Typical Chemical Analysis

| Cr | 16,00-20,00% |

| Ni | 7,00-9,00% |

| Si | 1,80-2,20% |

| Mn | 0,70-1,20% |

| C | 0,05-0,20% |

Cr Ni Si Mn C 16,00 - 20,00 % 7,00 - 9,00 % 1,80 - 2,20 % 0,70 - 1,20 % 0,05 - 0,20 %

Stainless Steel Shot Uses

- Aluminum Castings & Parts

- Non-Ferrous Metals & Alloys

- Investment Castings

- Die Castings

- Stainless Steel Equipment & Fabrication

- Sand removal

- For usage in sand blasting cabinets.

- Descaling

- Micro & structural blasting

- Cleaning of aluminum & different non-ferrous parts.

- Surface finishing of stainless steel parts.

- Zinc pressure die castings.

- An alternative for glass beads.

Spherical stainless steel shot abrasive is employed in each of applications wherever ferrous buildup is a liability & undesired. Stainless steel shot is usually employed rather than glass beads caused by its inferior dust, additionally inferior abrasive consumption & smaller waste. Stainless steel shot abrasive is appropriate for usefulness in wheel shot blasting machines in addition sand blasting nozzle. Stainless steel shot is ideally employed for cleaning, deburring, peening, descaling, roughening & surface.

Stainless steel shot is generally employed in the cleaning & finishing of stainless steel & non-ferrous surfaces wherever ferrous exterior contamination is undesirable, such as:

Features of Stainless Steel Shot

- Long lasting

- Uniform cleaning

- Gloss effect

- Corrosion resistant

- Accurate shape

The usefulness of stainless steel shot suggests a natural ecological option for different exterior restorative solutions, like garnet & aluminum oxide sand blasting, whichever develops much additional waste & dust emissions, & chemical processes such as acid pickling.

Stainless steel shot media is reusable & completely recyclable & complies with the strictest health & safety regulations. Improves cleaning efficiency while maintaining a desired appearance caused by its mass & appropriate hardness.