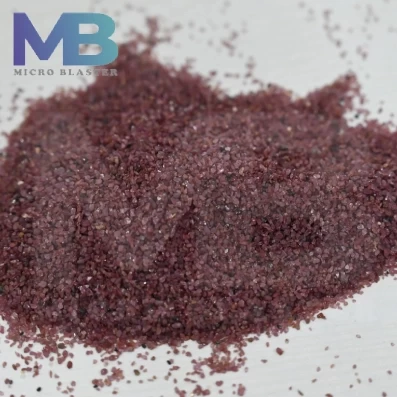

Garnet Sand 80 Mesh

| Brand Name | Abrasive Grit |

| Material | Garnet Sand 80 Mesh |

| Packaging Size | 25kg / 50kg / 1 Ton Jumbo Bag |

| Size (mm) | 0.177 MM |

| Color | Reddish |

| Specific Gravity | 4.0 - 4.1 |

- Garnet abrasive is typically utilised as a high-performance blast media for cleaning aluminium and fibreglass constructions.

- Garnet Abrasive is semi-reusable and can be re-used numerous times if used properly. It does degrade faster than totally reusable abrasives like aluminium oxide.

- Garnet sand is a good abrasive and a common sand blasting alternative for silica sand.

Garnet Sand 80 Mesh Manufacturer

Garnet 80 mesh may be a proper Abrasive Media and a well-liked replacement for silica sand in sand blasting machine. Alluvial garnet grains which are rounder are more proper for such sand blasting machine operations. Combined with very high-pressure water, the garnet sand manufacturer is used to chop steel and other elements in water jets. For water jet cutting, garnet extracted from hard rock is proper since it's more angular in form, therefore simpler in cutting. It also used for Typical filtration media and heavy shot blasting machine operations. Its minimum order Quantity is 25 Ton.

Applications of Garnet sand 80 Mesh

1) As an abrasive garnet can be broadly divided in two categories, blasting grade and water jet grade. The garnet manufacturer, as it is mined and collected, is crushed to finer grains; all pieces which are larger than 60 mesh (250 micrometres) are normally used for sand blasting. The pieces between 60 mesh (250 micrometres) and 200 mesh (74 micrometres) are normally used for water jet cutting. The remaining garnet pieces that are finer than 200 mesh (74 micrometres) are used for glass polishing and lapping. Regardless of the application, the larger grain sizes are used for faster work and the smaller ones are used for finer finishes.

2) Garnet sand is a good abrasive, and a common replacement for silica sand in sand blasting. Alluvial garnet grains which are rounder are more suitable for such blasting treatments. Mixed with very high-pressure water, garnet is used to cut steel and other materials in water jets. For water jet cutting, garnet extracted from hard rock is suitable since it is more angular in form, therefore more efficient in cutting.

3) Garnet paper is favoured by cabinetmakers for finishing bare wood.

4) Garnet sand is also used for water filtration media.5) Used in non-skid surfaces and heavily as a semi-precious stone.

Packaging Details

Garnet sand 80 mesh

- 25kg per bag, then 40 bags put in 1 ton (2200lb) bag.

- 25kg per bag, then 40 bags shrink wrapped onto 1 ton (2200lb) pallet.

- 1000kg (2200lb) loose in a one-ton bulk bag.

Chemical Properties of Garnet Sand 80 Mesh:

| specific gravity | 4.1 g/cm³ |

| hardness | 7.5-8 (Mohs) |

| melting point | 1310 °C |

| bulk density | 1.9-2.2 g/cm³ |

| Al2O3 | 25,00% |

| Fe2O3 | 30,00% |

| SiO2 | 35,00% |

| CaO | 2,00% |

| MgO | 7,00% |

| Product weight | 1.000,00 Kg |

| Contents | 1.000,00 kg |

Physical Properties of Garnet Sand 80 Mesh:

| Appearance | Red Sand |

| Odour | Odourless |

| pH | 8.0 to 9.0 |

| Vapour Pressure | Not applicable |

| Boiling Point | Not applicable |

| Radioactivity | Not detectable above background levels |

| Solubility in Water | Insoluble |

| Specific Gravity | 4.1 g/cm³ |

| Flammability | Non-flammable |

| Particle Size | The average range between 0.1 – 0.6mm, depending on grade |

| Particle Shape | Sub-angular |

Garnet Sand 80 Mesh Manufacturer in India

We are focused on our quality products and customer satisfaction. We provide abrasive Garnet Sand, Almandine Garnet Sand, Water Filtration Garnet, Garnet 12-24 Mesh, Garnet 20-40 Mesh, Garnet 30/60, Garnet 80 Mesh at low price at minimum delivery time. We are the leading manufacturer of steel shot, SS shot, copper slag, steel grit, garnet sand, quartz shot, aluminum oxide, glass beads, etc.

1. Particle size required (You may choose from above or give your own range).

2. Packing required.

3. Quantity required with a delivery schedule.

4. Destination port.

5. Payment terms.

6. Discharge rate at the destination, if in break-bulk.

7. Any other point which may impact the quote.