Acoustic Chamber

From the acoustic chamber fields in an acoustic tube with a unique resonator, the elements trials are calculated with two flexible parameters of the resonator expansion and sound influence level. The previous temporary works announced that baffled injectors show larger acoustic chamber in India, with gaps separating adjoining injectors than baffled injectors externally the gap or rigid baffles.

Product Details of Acoustic Chamber in India

| Usage of the acoustic chamber | Sound Absorbers |

| The material used in thermal spray acoustic enclosure | Steel |

| The thickness of acoustic chamber in India | An absorptive layer of 32kg/m3, 50mm thick |

| Type of thermal spray acoustic chamber in India | Acoustical Experiment Room |

| Application of thermal spray acoustic chamber in India | For measurement of the radiated sound from an object, or for the subjective listening test. |

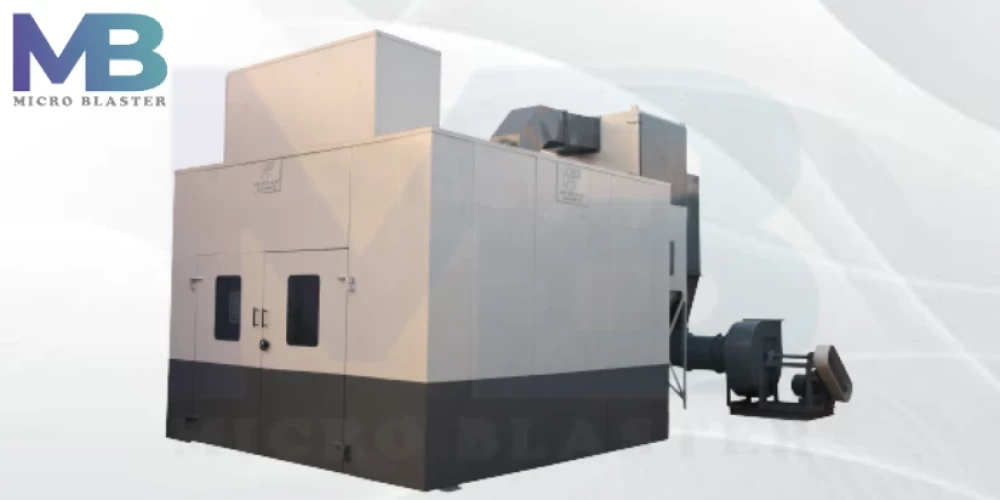

Thermal Spray Acoustic Chamber in India

We implement a thermal spray acoustic chamber in India involved in plasma spray gun coating, which further intends dust and noise presented by your thermal spray coating methods which can be done by thermal spray gun, arc spray gun, plasma spray gun, zinc spray gun, metalizing gun, and various others. An acoustic enclosure in India can be completely customized to modify your specific qualifications. Peculiarities include:

- 82″ x 84″ double-leaf access main door(can be sliding or 4 leaves sequentially as per the specification of the user).

- 30″ x 42″ viewing window(on the main door).

- Inlet silencers (up to 8000 CFM linked).

- Galvanized metal sheet wall strengthening is done of the thermal spray acoustic chamber in India which possesses a perforated sheet and glass wool which functions as sound using.

- The Air louver is established on the rooftop of the thermal spray booth for air consumption.

- Baffles Plate is determined in an air louver at an angle of 60 degrees so that fluctuation of sound cannot escape.

- A suction hood is settled inside the thermal spray acoustic enclosure in India which excludes airborne salve, fumes, heat, and fumes from the air by the abandonment of the air and filtration.

- The suction hood can be of two types like when the intention is spherical the back wall of the suction hood is succeeded as round and when the object is oblong or square then it will be a plain surface. If used for both the purpose by you then there is fascinating bend at the back wall of the suction hood.

- Joinery of the slab to slab can comfortably be sealed with Poly Urethane Foam-based components to create seamless interactive.

- UV 10 roll-down shade.

- Standard firm beige paint, custom colors achievable.

Each structure is manufactured to reduce the high sonance levels of thermal spray coating to a satisfying 85 dBA. The thermal spray acoustic enclosure in India is generated from panels and joiners, getting their device extremely flexible. Prepared for preferred sound keen-sightedness, the panels affect high-quality acoustic chamber manufacturer in India dimensions and perforated steel sheet on the internal covering. The modular succession of the acoustic chamber manufacturer in India allows for the merest modification time and tranquil relocation of the thermal spray acoustic chamber in India. Conventional spray-room canopy altitudes are 8 or 10 ft. (2.1 or 3.1 m). The insets come in a variation of sizes, with appropriate sizes supplied as commanded. The thermal spray booth comes terminated with floor channels, stiffeners, and joiners.

Appearances of Acoustic Enclosure in India

- Brilliance

- Ensemble

- Clarity

- Warmth

- Texture

- Blend

- Focus on sound

- Fulness

- Intimacy

- Reduction in the concentration of sound

- External noise

- Rectangular usage room

- Flutter echos from laterally walls

- High absorption coefficient

- Easy to handle, clean, and install

Acoustic Chamber Manufacturer in India

We are the leading Acoustic Chamber Manufacturer and Supplier of thermal spray acoustic enclosure in India. We have providentially prolonged its vindication in the market owing to the esteemed superior quality association of the thermal spray acoustic chamber in India. Along with thermal spray acoustic chamber manufacturer, we also produce a shot blasting cabinet, blast rooms, sand blasting machine, portable sand blasting machine, grit blasting machine, etc. at an affordable price. The recommended acoustic chamber manufacturer, reserving preferred essence raw-material and the most exceptional technology. Furthermore, a string of our quality controllers extends a series of quality commentaries on the entire range to seek out whatever permissible mistake.

We prescribe some abrasive forecasters such as copper slag, abrasive garnet sand, quartz stone, steel grit, aluminum oxide, glass beads, steel shot, powder feeder, plastic abrasive media, etc. which are acknowledged by blasting machines. For the layer on the purpose, we use a thermal spray gun, flame spray gun, wire flame spray gun, arc spray gun, zinc spray gun, plasma spray gun, etc. at an inexpensive price. In total with global set standards, we provide the entire grassland of thermal spray acoustic enclosure in India of various dimensions and at industry affecting prices in Jodhpur, Rajasthan, India.